Pellets

Pellets – multiparticulate systems with numerous benefits

Pellets are small, spherical particles with typically smooth, low-porosity surfaces and an average diameter of 0.1 to 3 mm.

They can be filled into stick packs or capsules and formulated as dosage forms with immediate, modified, or site-specific release within the gastrointestinal tract.

Manufacturing of Pellets at Losan Pharma

Pellets can be manufactured by either layering the active ingredient onto starter cores or by extrusion followed by spheronisation.

Drug Layering

Layering is similar to a film coating process. One or more active ingredients are applied as a solution or suspension in successive layers onto starter pellets (e.g., sugar starch, MCC or tartaric acid spheres) measuring between 0.1 to 2 mm in diameter.

Extruded pellets

Extrusion pellets are produced using a granulation process. First a powder mixture of API and excipients is agglomerated with a binder, and the material is then pressed through an extruder die to produce high density extrudates. These are subsequently made into pellets through a spheronisation process.

Pellets can be further processed to various dosage forms, such as:

encased in capsules

filled into stick packs

compressed into tablets

Wide range of release profiles

Modified release formulations can help to reduce side effects and/or improve a drug’s efficacy.

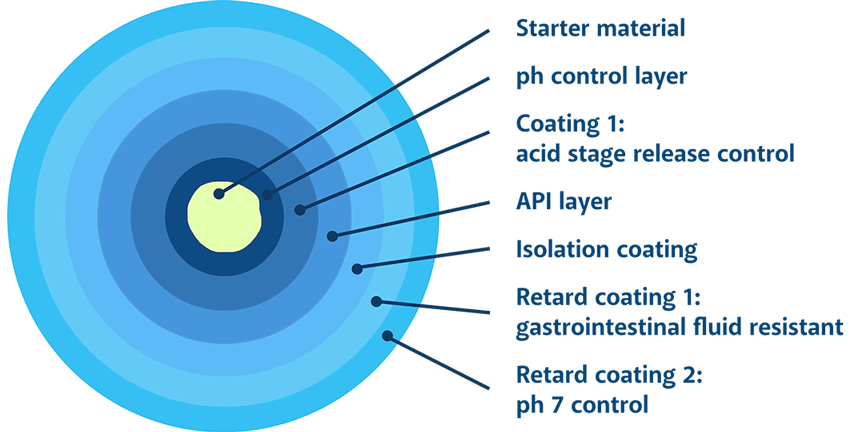

Thanks to our extensive know-how in fluid bed technology, we can apply different coating layers to each pellet. This enables us to produce pellets with targeted or extended drug release profiles.

Matrix formulations combining immediate release and extended release pellets (dual release) in capsules or stick packs can offer significant benefits for patients. (e.g., a medication normally requiring three tablets per day can be reduced to a single capsule or stick pack taken once daily).

Example of a tailored-release pellet formulation developed at Losan Pharma:

Improved Patient Compliance

Taste masking

Taste masking is essential for pellets in stick packs, which are taken orally.

Taste masking is usually achieved by applying a saliva-resistant coating to the pellets using fluid bed technology.

Pleasant-tasting flavour blends can further enhance mouthfeel and taste in direct-use formulations, making them ideal for pediatric applications

High API load

Pellets in stick packs are an excellent alternative dosage form for elderly patients and children who have difficulty swallowing large tablets. Stick packs can also carry than tablets or capsules.

Our patented Vismon® coating makes it easier for patients to swallow pellets when they are taken directly without water.

Upon contact with saliva, the coating swells to form a smooth, cohesive pulp of multiparticulates, which helps patients to swallow (even larger quantities) more comfortably.

Combination products

By combining various API pellets in a single capsule or stick pack, combination products can be created that reduce the number of tablets patients need to take each day.

Pharmaceutical pellets services

Clinical trial supply through all clinical phases

Scale-up from pilot scale to commercial scale

Commercial manufacturing

Extensive down stream capabilities

Advantages of our pellets

The main advantages for the development and use of pharmaceutical pellets are:

Offers flexibility in dosage form design and the modification of release profiles

Allows incompatible drugs to be combined

Enables higher drug loads compared to tablets

Makes swallowing easier thanks to our Vismon® coating technology

Avoids high local concentrations as they disperse freely in the GI tract

Minimises potential side effects without decreasing bioavailability

Reduces fluctuations in plasma levels (compared to monolithic forms) due to the multiparticulate distribution of particles in the GI tract

Losan Pharma stick fillings: pellets | mini tablets | high dosage granules and blends